For various carbon graphite products, although they already have a certain shape and size after forming, they will undergo expansion and contraction, deformation and bending damage during the process from crushing through roasting, impregnation and graphitization to graphitization blanks. Or drop corners, because the surface is rough and uneven due to the adhesion of some fillers and insulation materials, its shape and size have changed to a certain extent, so it cannot meet the strict requirements for the shape, size and surface roughness of the product during use. Therefore, Carbon graphite products cannot be used without machining. In addition, some products have complex structures and shapes that cannot be directly produced by forming methods, such as metal continuous casting and rolling graphite crystallizers, graphite molds for EDM, graphite boats and discs for cemented carbide sintering, and other special graphite products. There are also some products that need to be connected to each other when they are used. The connecting threads of steelmaking electrodes and joints, the brush braids of electric brushes, and the dovetail grooves of carbon blocks, etc., all need to be machined before they can be manufactured. Therefore, the purpose of machining carbon and graphite products is to make the product meet the special requirements for shape, size, surface roughness and others during use.

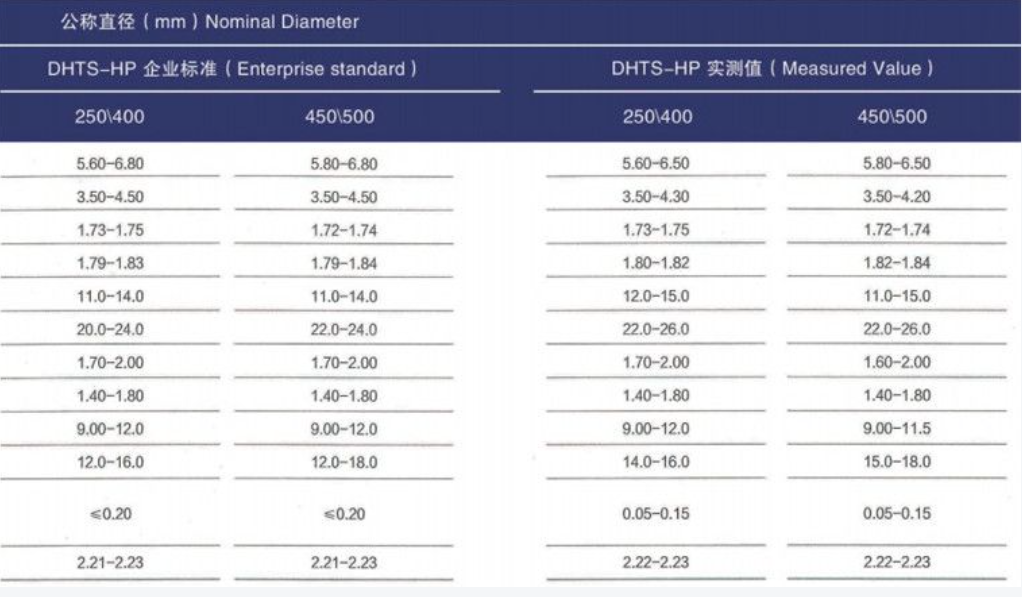

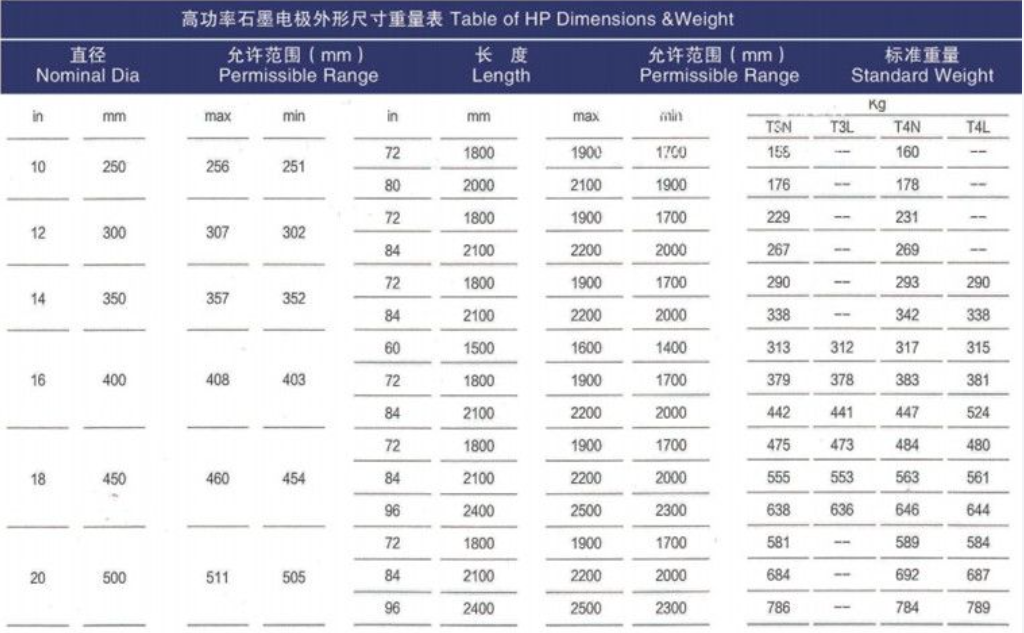

Parameter Display

Products Describe

The resistivity of the graphite electrode is a physical index that reflects the electrical conductivity of the electrode. It is related to the manufacturing process of the electrode. Our country has the qualitative regulation value to the graphite electrode resistivity of different specifications and varieties. In general, steel factories in the selection of a certain specification of the electrode, must choose in the range of national metallurgical standards specified resistivity, excessive electrical resistivity will cause the electrode to become red and hot when energized, increase electrode oxidation consumption.

Packing and Shipping

FAQ

1. How could I get a quick quotation?

A: With the following information, it will help a lot for a quick calculation of price for you:

Firstly, A drawing or detailed explanation of graphite dimensions.

Secondly, Graphite material technical specifications, or alternatively applications of your required graphite products.

2. What is export percentage in your company whole business?

A: over 95%. Main customers distribution: Korea, Japan, Indonesia, Malaysia, Taiwan, South Africa, Russia, Austria, Germany, UK, Spain, France, Italy, Luxemburg, USA, Australia, New Zealand, Argentina etc.

3. Is your company a manufacturer?

A: Yes

4. What services can we provide?

A: Accepted Delivery Terms: FOB, EXW, Express Delivery;

Accepted Payment Currency: USD, EUR, HKD, CNY;

Accepted Payment Type: T/T, Credit Card, PayPal, Western Union, Cash;

Language Spoken: English, Chinese

5. Why should you buy from us not from other suppliers?

A: Our company is specialized in producing all kinds of high purity, high strength, high density graphite and ceramic product , we have experience engineers to design all kinds of size products, we have advance machines and excellent workers operating.

Inquire Basket (0)